About ReMed

Background

The quantity of small Medical Devices (MDs) in waste streams has escalated in recent years, due to a proliferation of medical treatments in both range and number, their inherent reliance on the use of medical devices, and rapid growth in the number of patients seeking the most advanced treatments globally. Small MDs are mainly hand-held or portable, and examples are patient monitors (blood pressure, glucose, gluten, sleep, pulse), inhalers, defibrillators, oxygen machines, smart thermometers, infusion pumps, intraoral cameras, electrical thermal pads and other pain relief devices, small surgical tools, insulin pens, catheters, and custom packs. The UK’s MD registration database has over 4,500 items.

Aims

In order to tackle the problem of the prevailing linear model (cradle-to-grave), this research adopts a Circular Economy (CE) approach to reducing small MD waste. The CE is a term applied over the last decade to a system in which material resources and value are retained to perform useful functions, rather than being lost in landfill or converted to energy.

The overall project aim is to develop ‘whole system’ reference models based on products representative of their type, to provide new, ambitious references for the small MD producer and waste management industries to emulate. In this way, the high costs and environmental impacts currently associated with the linear life paths of many such devices can be significantly reduced.

Methodology

Four reference case study products are selected in consultation with industry partners, considering their aggregate value and complexity of circular options, as depicted in the figure. These include:

- Multilayer Polymer Intravenous Fluid Bags

- Surgical Tools

- Inhalers

- Blood Glucose Monitors

All the above are, respectively, representative of passive polymer MDs, metallic tools, EE delivery MDs and EE monitoring MDs. These exemplify the common challenges preventing application of the CE, being single life and infectious; lack standard product structures to aid with reused or remanufactured; and multi-materials and parts with complex geometries which makes high-quality material reclamation infeasible.

The knowledge created through research on these case study reference products will be widely transferable and applicable in similar product families, providing potential for creating wide range of impacts beyond the specific project boundaries.

Challenges

The Circular Economy (CE) is gaining mainstream attention, but not in Healthcare sector. The linear model, from cradle to grave, still prevails for small Medical Devices (MDs) due to a range of challenges including:

- Badly designed products, for example:

- Planned obsolescence

- Excessive packaging

- Unintuitive or unergonomic design

- Strict and rigid material regulation

- Cost effective decontamination

- Operational issues regarding waste collection

- Bespoke remanufacturing and recycling technologies

- Circular business models

Work Plan

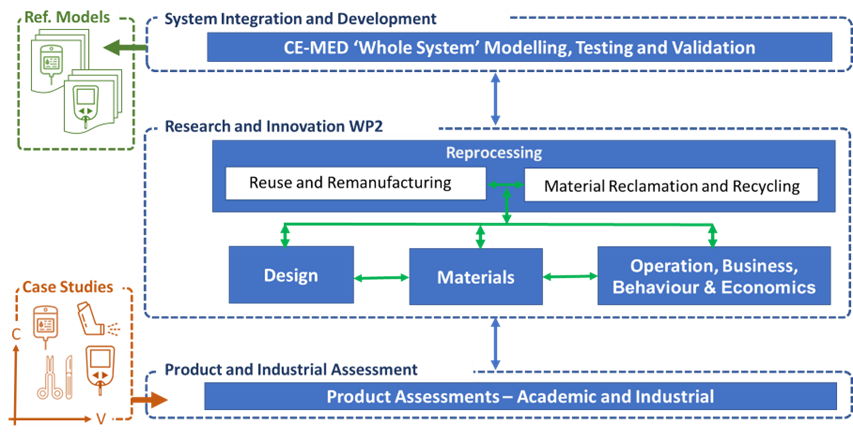

The work plan uses the framework shown in the figure below. This recognises that design for circularity is critical for success; materials with properties which can reconcile the conflicting requirements for functionality, integrity following sterilisation treatments and recyclability (among other requirements) need to be developed; reprocessing equipment needs to be configurable to deal with the many and varied types of small MDs; and the management of the device life-cycle must be optimised if these new technical aspects are to deliver benefits.